Aircrafts have changed our way of life. We can reach almost anywhere on the planet in two days or less, and this speed has taken our societies to new heights. It’s amazing to think about the sheer weight of a plane soaring in the air, however, an aircraft’s ability to simply roll down a runway is just as amazing!

Two factors make it possible for an aircraft to achieve the speed for takeoff, which are tires and airfield surfaces, and both factors are highly lucrative businesses. In 2020, the global aircraft tire market was valued at $1.52 billion, and it is projected to nearly double to $2.85 billion by 2030. Furthermore, the surging demand for air travel will increase the world’s airport construction market to $1.8 trillion by 2030, amassing a $500 billion growth from 2022.

How are two of the simplest raw materials, rubber & aggregate, so vital to the 120-year history of aviation, and so essential to the projected economic growth of the next decade?

Early Years of Flight

The first pneumatic rubber airplane tire was developed in 1909, six years after the Wright brother’s first flight. Prior to the novel product, aviation pioneers used sled runners, heavy motorcycle tires, or even bicycle tires which tended to rip off upon landing. Goodyear Tire & Rubber Company led the development of the first aircraft specific tire, knowing the tire didn’t have to travel far, but had to withstand hard impacts.

“On the basis of the flyer’s recommendations, we built some experimental tires, tested them by dropping them off the roof of a three-story building on a concrete court. They worked out satisfactorily and soon everybody was using them – though this was not much of a compliment, as ours was the only one on the market.” –

Paul W. Litchfield, Goodyear Tire & Rubber Company

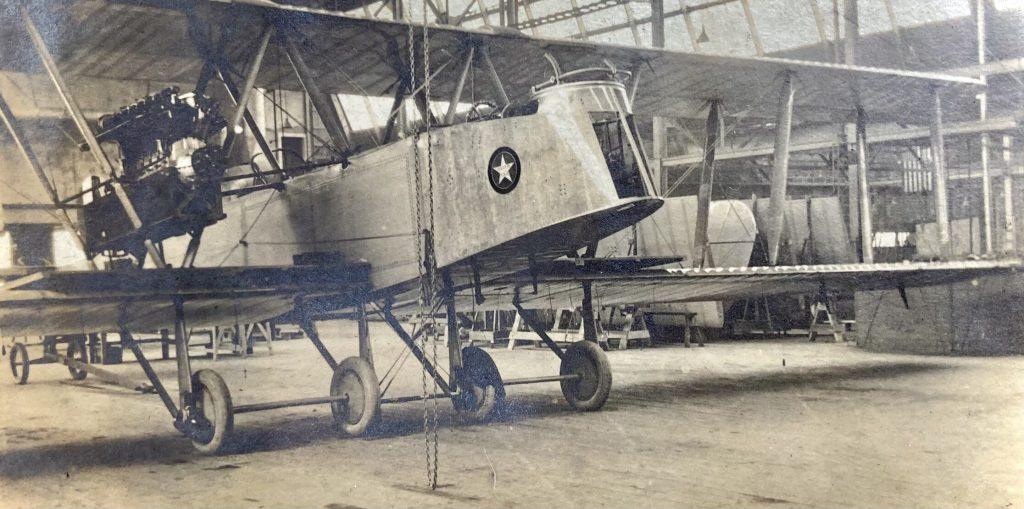

With further input from the flying community, the first pneumatic aircraft tire was redesigned a year later, this time using cord fabric and a wire bead, and the improved design ultimately remained the standard for twenty years. In 1918, the U.S. Army began to fly the most advanced bomber in the world, the Martin MB-1. This wood-framed aircraft was the first bomber built by the United States and had a maximum takeoff weight (MTOW) of 10,225 pounds, which included an over 1,000-pound bomb payload. Even by today’s FAA standards, this is just shy of the 12,500-pound weight threshold to be considered a “large aircraft.” To distribute the hefty load, the aircraft utilized a distinct, fixed main landing gear consisting of four-wheels, and a typical fixed taildragger wheel.

By 1928, problems began to rise as aircraft weights continued to increase, and the planes struggled to traverse on the primitive mud, sand, and thin pavement runways. Goodyear Tire & Rubber Company devised a larger tire to ride on extremely low air pressure, essentially a “floatation” tire to roll over rough ground instead of rutting. However, the larger tires only masked another underlying issue, airfield surface conditions.

Lessons from WWII

In 1941, the U.S. completed the Douglas XB-19, an experimental heavy bomber. At the time, it was the largest bomber aircraft built with a boastful MTOW of 162,000 pounds, which included the max bomb load capacity of 37,000 pounds. The aircraft utilized a tricycle landing gear configuration, with the two massive main gear wheels showcasing 96-inch diameter tires with 24 plies, and each wheel assembly weighed 2,700 pounds.

On 6 May 1941, the behemoth bomber rolled out of the hangar for the first time and literally broke through the asphalt pavement to a depth of one foot. Efforts to move the heavy bomber continued, and it was towed under much strain to the asphalt runway but caused noticeable damage to the airfield surfaces. It took nearly two more months for the maiden voyage to occur on a newly constructed concrete runway.

Prior to this incident, airfield designs were based off automotive highway knowledge and experience, but now geotechnical engineering for aircraft was of greater importance. Within a year, O. James Porter devised a new test and measure called the California Bearing Ratio (CBR), which became the principal method to design asphalt pavement by evaluating the shear resistance of base and subbase materials.

Also in 1942, Dr. Arthur Casagrande developed the “Airfield Classification” system to further understand soil behavior characteristics that are pertinent for design consideration. This early system expanded into what is now the Unified Soil Classification System (USCS), which is used to define grain-sizes as cobbles, gravel, sand, and fines, and further examines the plasticity and dry strength of the fines material.

General Henry H. Arnold, Commander U.S. Army Air Forces

“Air bases are a determining factor in the success of air operations. The two-legged stool of men and planes would topple over without this equally important third leg.”

Arguably, the XB-19 produced more civil engineering knowledge than aeronautical engineering knowledge. In-situ soil continues to be a major factor to airfields, as it ultimately sustains the high wheel load stresses acted upon the pavement. Additionally, pavements require a careful design of layer strength and thicknesses to ensure the capability of carrying a given tire load, and now, stresses from multiple-axle bogies.

Modern Era

Typical of human behavior, build it bigger continued to be an aircraft design endeavor. To date, the Antonov An-225 Mriya is the aircraft that surpassed all in the weight category. The strategic cargo aircraft built by the Ukrainian company made its maiden flight on 21 December 1998. The jet has a main landing gear arrangement with seven pairs of wheels on each side, and two additional two-wheel bogies below the nose. All 32 wheels are used to enable the record setting MTOW of 1,322,275 pounds, which includes the 551,146-pound payload capacity.

Creating and flying very large aircraft (VLA), such as our modern-day cargo and passenger planes, also advances the world’s main aircraft tire manufacturers: Goodyear Tire & Rubber Company, Michelin, Bridgestone Corporation, and Dunlop Aircraft Tyres. An average commercial aircraft tire costs $5,000 each but can be retreaded seven times or more. There are many factors that play into the lifespan of a typical aircraft tire, but they are generally designed and constructed to last anywhere from 120 to 400 landings.

Aircraft tires are a mix of bias ply or radial design, tubeless or innertube, and innovative safety technology such as a fusible plug to avoid blowouts from occurring. Commercial and military main gear tires can range from 56 to 360 psi ratings, with individual load ratings of 60,000 pounds, all while resisting distortion during high speeds.

The strength of a tire is derived from its casing plies, and strong beads are used to hold the tire on its wheel. Recently, Goodyear Tire & Rubber Company developed what they coined Featherweight Aluminum Core Bead Technology, an innovative cord bead that maintains tire strength and durability but reduces the overall weight of a tire. This may not seem vital but remember some planes can use upwards of 32 tires!

On the Horizon

The next time you are seated comfortably on an aircraft, and you begin to roll down a taxiway and turn to speed down a runway, be sure to marvel at the engineering involved to get you up to that point…before the nose of the plane rotates to the sky and the wings lift the aircraft. Over 120 years ago, the largest aircraft weighed nearly 12,000 pounds, and now we have passenger planes that can weigh 1,200,000 pounds, a growth factor of 100 times!

I’m sure we can build bigger aircraft, but do we need to? The future goal may need to be sustainability, in all factors such as aircraft fuel sources and efficiency, tire life and manufacturing, and pavement materials and design. After all, we are only talking about highly inflated rubber containers of air, traversing over compacted rocks and binder, under extreme loads of tens of thousands of pounds…simple science, right?

Additional Notes: All three of the aircraft assessed in this article now cease to exist. None of the original 20 built Martin MB-1 aircraft remain, but there is a full-scale reproduction of its successor, the Martin NBS-1 (MB-2), at the National Museum of the U. S. Air Force. The only Douglas XB-19 aircraft built was scraped shortly after WWII, but two of its enormous main tires were saved. One tire is on display at Hill Aerospace Museum, and the other at the National Museum of the U.S. Air Force. The only Antonov An-225 built was destroyed in the Battle of Antonov Airport, during the Russian invasion of Ukraine, in February 2022.

Disclaimer: The views of this article belong to the author and do not represent the official views of the United States Air Force.

Jason Lawyer is a military professional with 15 years of experience working in multiple civil engineering disciplines. He loves all things pertaining to the transportation industry, including the infrastructure needed to support. He has a passion for research and enjoys sharing exciting discoveries. He lives with his wife and children in North Dakota.

A list of full references for this article can be found on Jason Lawyer’s Linkedin profile